Energy efficiency

Energy efficiency review

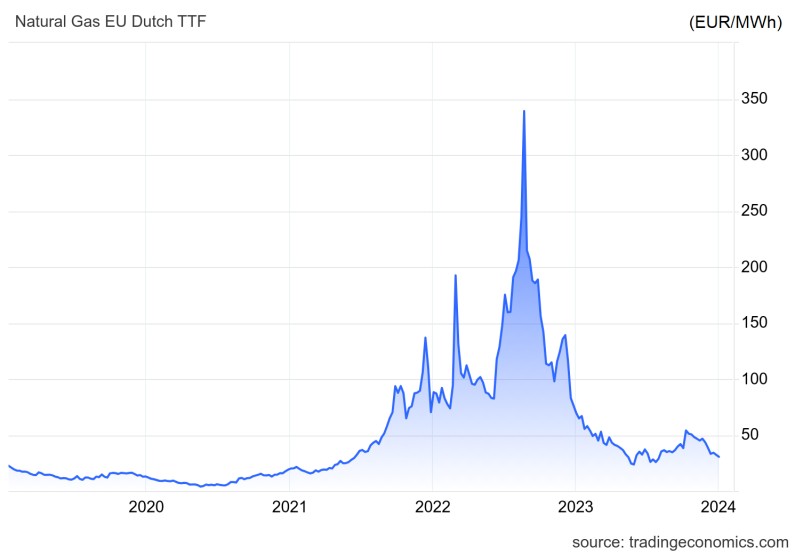

Due to the uncertain and constantly changing energy market situation, it is essential for manufacturing companies to conduct a comprehensive energy audit of their production units. Through the preparation of an in-depth energy study, we ensure the development of a long-term energy saving strategy. The review includes the analysis of energy flows, mapping of waste heat sources, assessment of energy distribution system faults, inspection of pipeline network conditions, and determination of energy losses.

During the study, we also examine the feasibility of operating centralized and decentralized heat sources, as well as the integration of technological waste heat sources.

The assessment is carried out on three levels:

- site-level energy distribution system

- evaluation of building energy efficiency

- evaluation of equipment efficiency

The main focus is on the energy solutions of the heating network, but it also covers comfort ventilation, comfort cooling, and technological cooling systems.

A comprehensive assessment of a large industrial site typically takes around 3 months.

The process consists of the following phases:

1. Data collection

- Gathering 3 years of operational data and performance records

- Collecting relevant architectural, mechanical, and electrical drawings, information, and equipment manuals

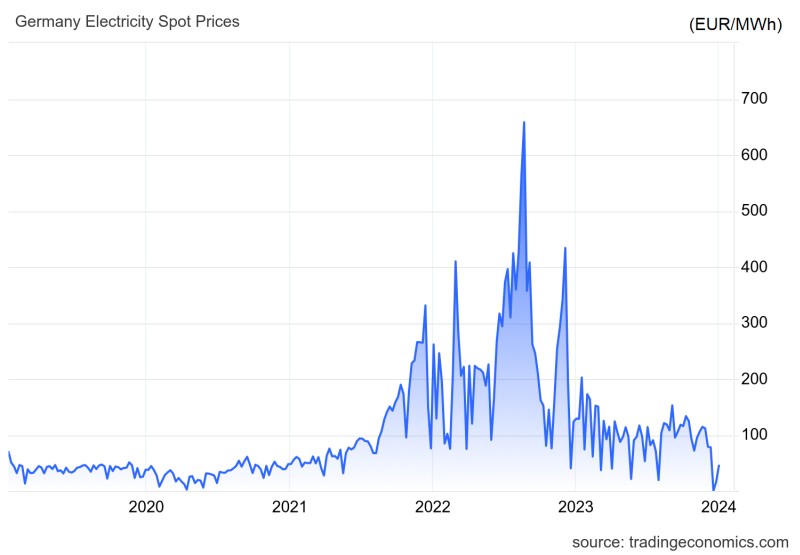

- Determining cost bases (gas, electricity, and other utilities) and reviewing the primary energy carrier structure

- Establishing energy flow models and system boundaries

- Analyzing relevant operational processes

2. Evaluation and preparation of a detailed study

- System-level assessment of mechanical systems

- Identification of primary focus areas, mapping potential waste heat sources

- Analysis of energy distribution

- Analysis of end-use and consumption

- Detailed review of energy management practices from an operational perspective

- Examination of secondary consumers

3. Decision support study and executive summary

- Executive summary including an actionable list of tasks,

- CAPEX and OPEX estimates, as well as BMR calculations for short-, medium-, and long-term development opportunities

- Design recommendations

We also undertake the detailed design and permitting of systems based on management decisions derived from the study.

The study covers the following technical disciplines:

- heating

- cooling

- process cooling

- ventilation

- steam systems

- compressors

- main electrical consumers

- lighting modernization

Following the assessment, an executive summary is prepared, which serves as the basis for short-, medium-, and long-term reconstruction planning.

Construction engineering design

Mrs. Éva Siket

+36-70-588-6008

Mr. Balázs Nyári

+36-20-480-9348

MEP Q Engineering Ltd.

Tax number: 12514658-2-42

Company registration number: 01-09-690178

Bank account number: 12011179-01480799-00100005