Energy efficiency 2024

In the study we examine the possibility of operating centralized and decentralized heat sources and the integration of technological waste heat sources

Heat pumps, gas operated absorbers, adsorption cooling, condensation heat utilization and adiabatic cooling are also the subject of the study.

The examination is performed on 3 levels:

- energy distribution system

- examination of the energy efficiency of buildings

- examination of the efficiency of devices and systems

The main focus examines the heating energy, but includes the comfort ventilation, comfort cooling and technological cooling systems.

The study covers the following disciplines:

- heating,

- cooling,

- technological cooling,

- ventilation,

- steam systems,

- compressors,

- main electrical consumers

- lighting modernization

After the due diligence, a general summary is prepared, introducing short-, medium- and long-term reconstruction plans.

An inspection of a larger factory takes approximately 3 months.

It consists of the following phases:

1. Data collection

- Collection of operational data and operational experience going back 3 years

- Collection of relevant architect, mechanical and electrical plans, information, manuals

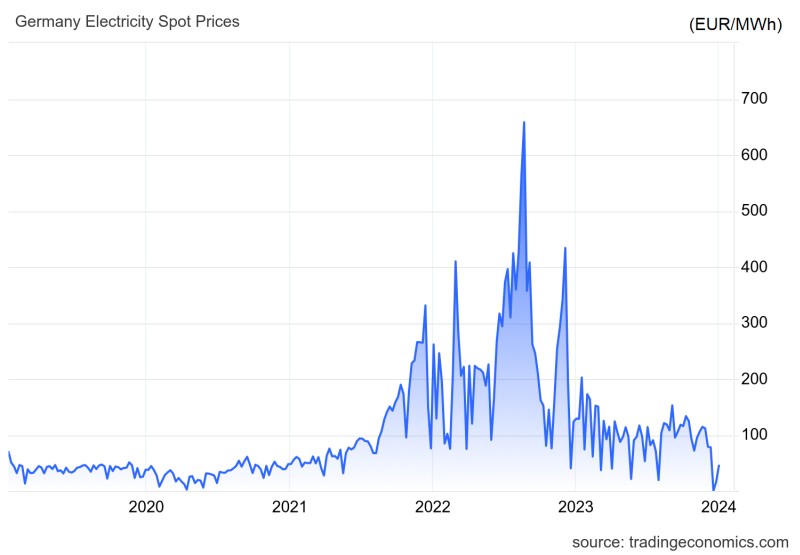

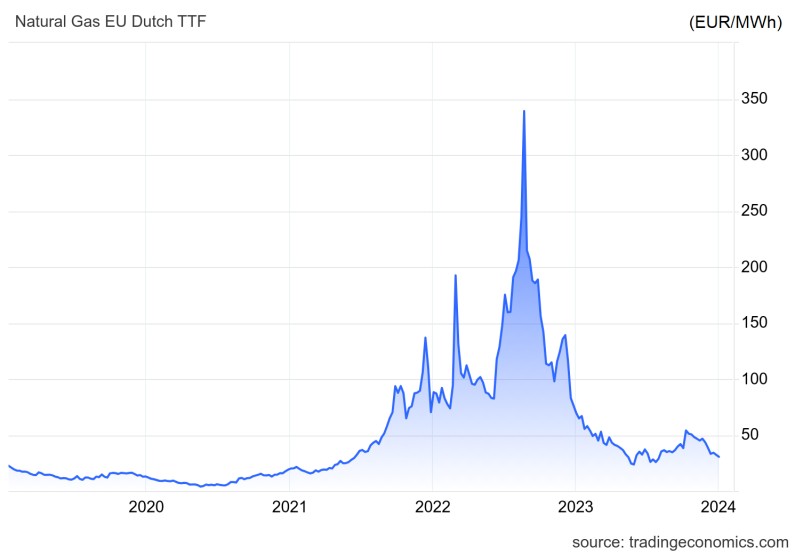

- Determination of cost bases (determination of gas, steam, electricity cost items), overview of basic energy carrier structure

- Setting up energy flows, acquiring and building system diagrams

- Analysis of relevant processes

2. Evaluation, preparation of a detailed study

- Deep inspection of mechanical systems

- Laying of primary focuses, mapping of possible waste heat sources

- Analysis of energy distribution

- End use/consumption analysis

- Energy management

- Examination of secondary consumers

3. Compilation of the general summary, the decision preparation study and the executive summary

- Executive summary, which includes the tasks that can be performed in a list,

- CAPEX and OPEX estimates of short-, medium- and long-term development opportunities, BMR calculations

- Design recommendations

We also offer the executon design and permission of the selected systems, based on the study.

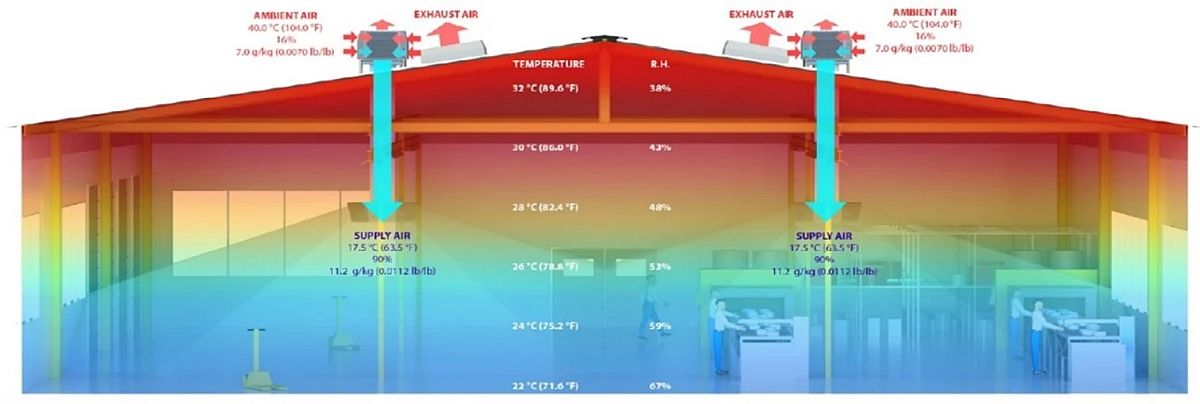

Innovative hall cooling technologies

The systems are suitable for complete hall cooling, or even just for pre-cooling purposes, with minimal energy requirements, high efficiency, and quick payback.

Realized projects:

- Certa Sátoraljaújhely

- Knott Cegléd

- Alkotás Point Irodaház Budapest

- Interple Tárnok

- Toyo Seat Százhalombatta

- Ruag Eger

- Claas Törökszentmiklós

- Nestlé – Purina

Do you need a team of experts?

Construction engineering design

Mrs. Éva Siket

+36-70-588-6008

Mr. Balázs Nyári

+36-20-480-9348

MEP Q Engineering Ltd.

Tax number: 12514658-2-42

Company registration number: 01-09-690178

Bank account number: 12011179-01480799-00100005